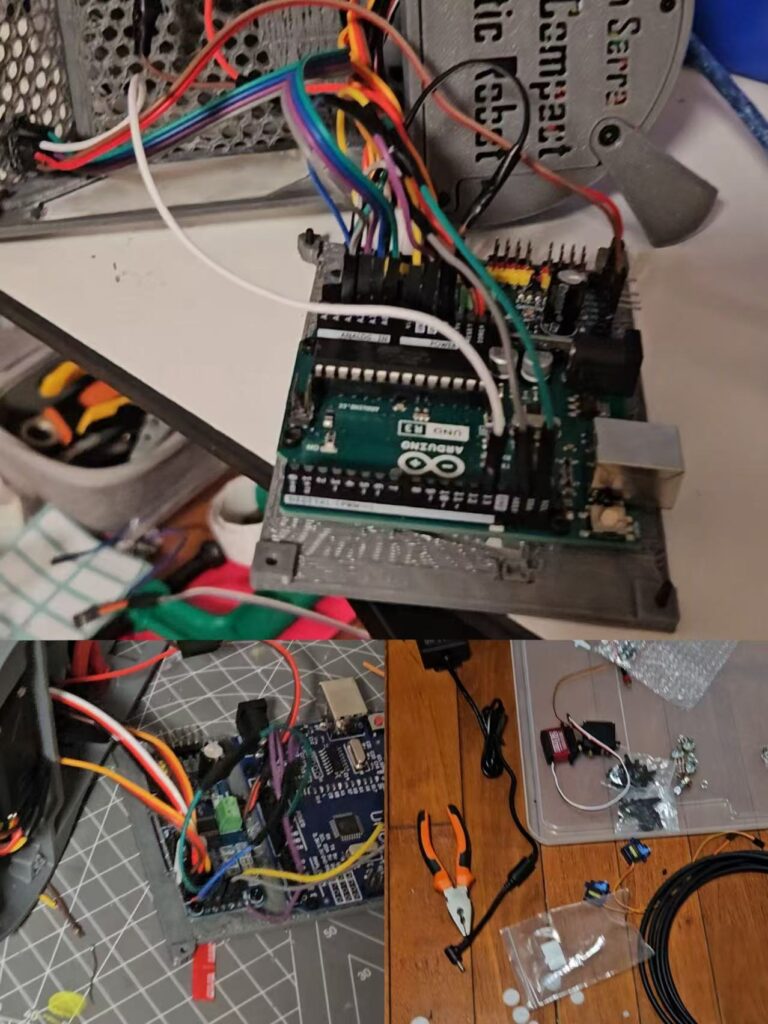

After my first success, I felt even more confident and passionate about building robotic arms. I found a more advanced robotic arm project on GitHub, and ordered the 3D-printed parts and components from Taobao. I have to say, Taobao is amazing—cheap and fast. Soon, I started working on the project.

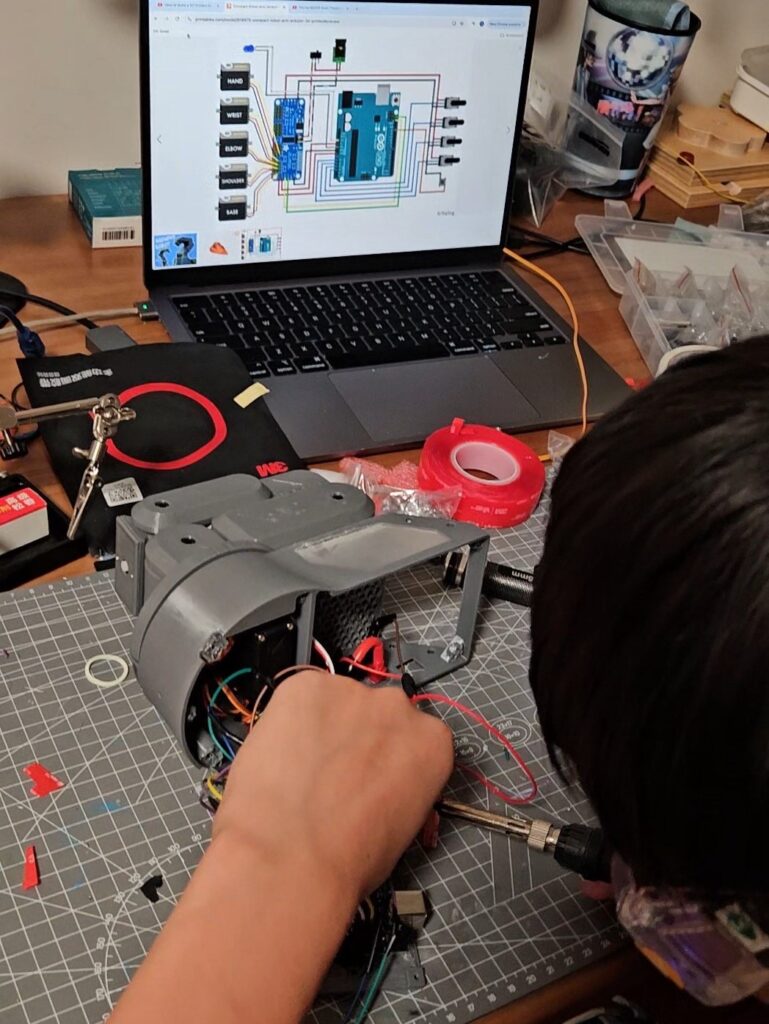

This time, the concept was to use a small robotic arm to control a larger one. The small arm was connected with resistors, and through algorithms, it could control the larger arm. It’s like when you move your hand, and the big robotic arm follows your movements. I thought this was really interesting and had many potential applications.

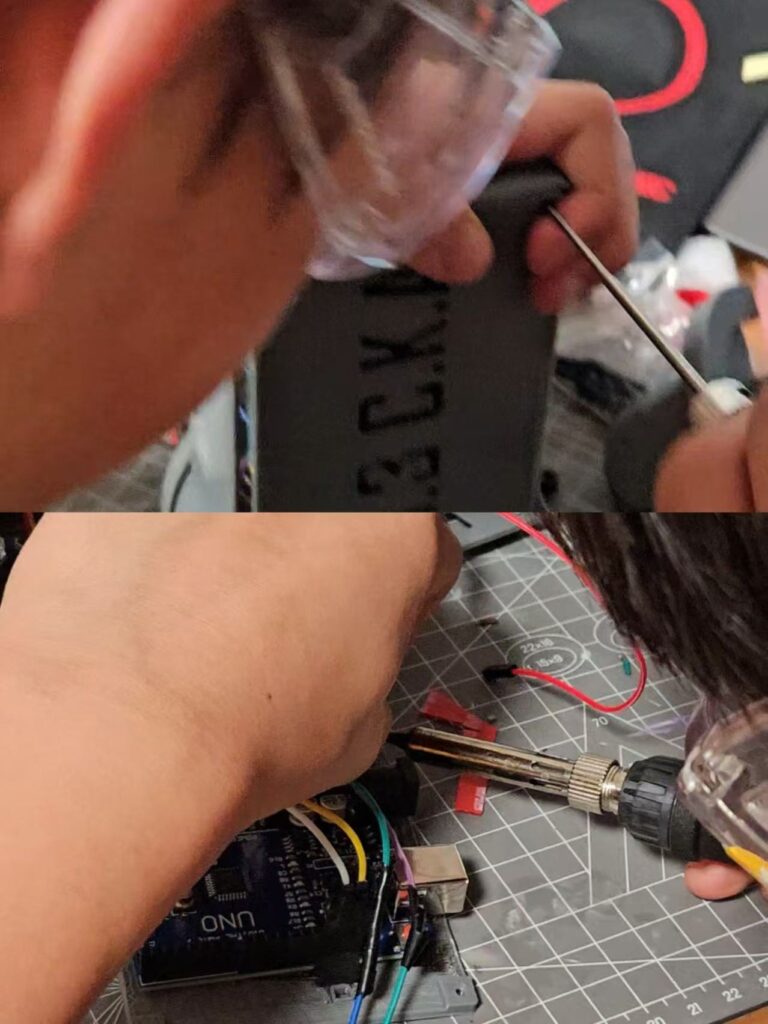

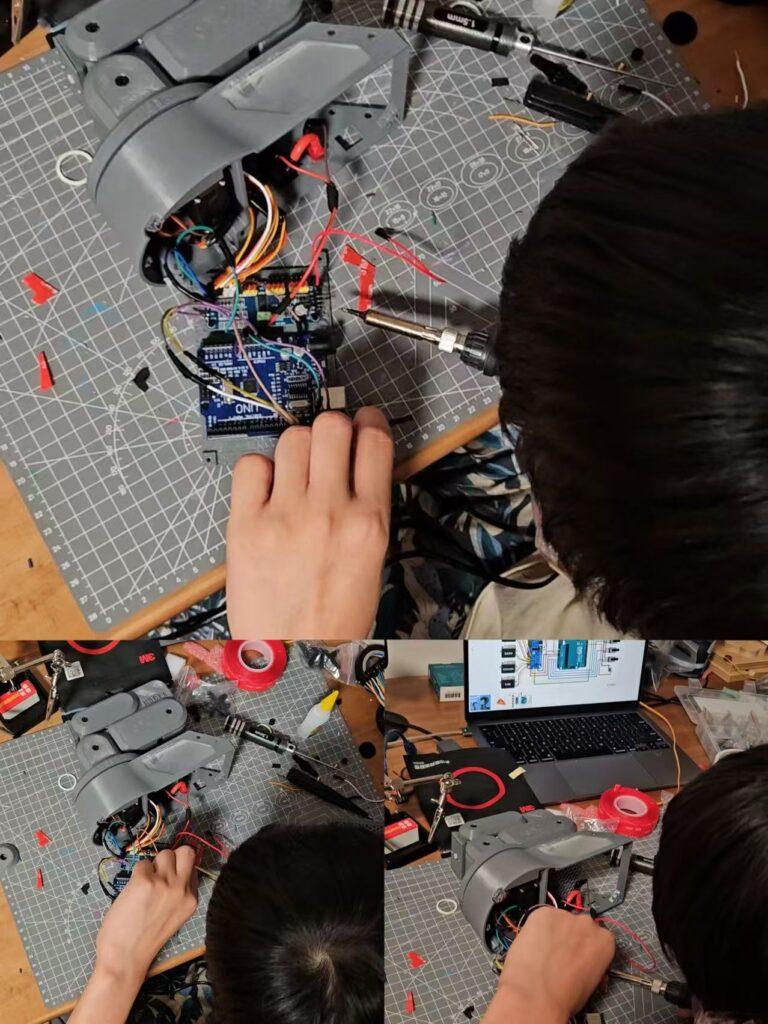

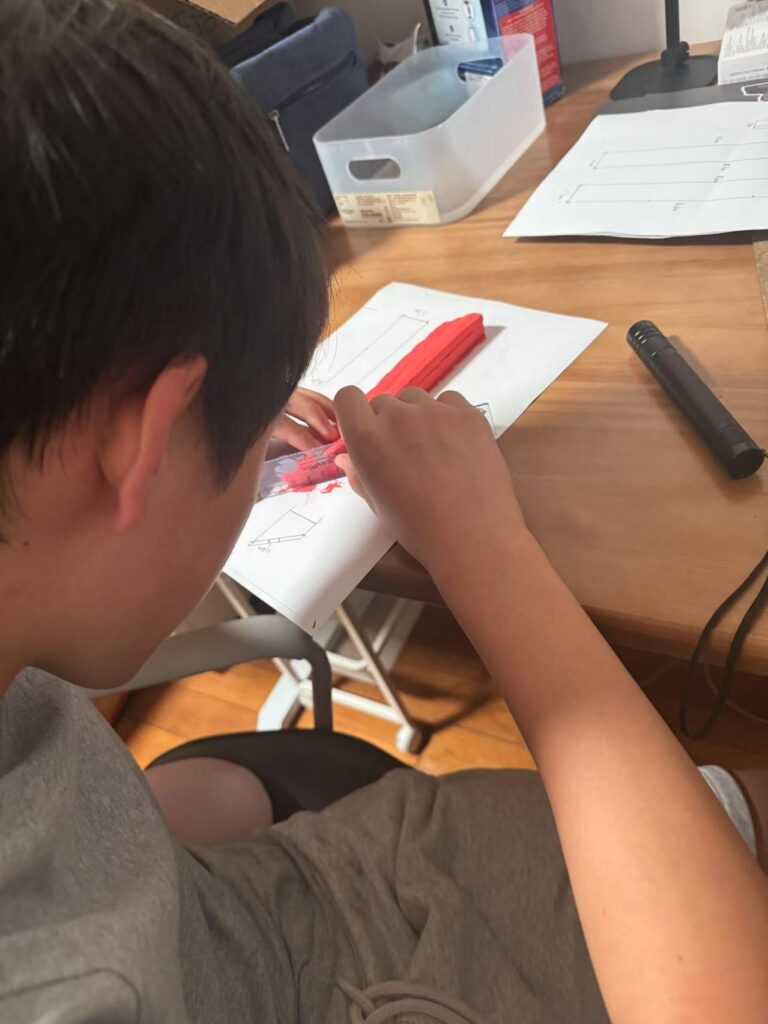

At the beginning, I wasn’t discouraged by the complicated challenge of soldering circuit boards. I often stayed up until 3 or 4 a.m., redoing my work if the soldering didn’t look neat. I even found it fun to connect all those colorful wires. While soldering, I tested each step carefully. Since a mistake early on could mean starting over from scratch, I followed the instructions step by step with great caution.

After two weeks, I finally completed it—the small robotic arm could indeed control the larger one! I was really excited. However, I later discovered that my circuit board had some issues. Even after buying a new one, the full functionality still didn’t work. In the end, only the top rotation and gripping functions were successful. I suspect I might have accidentally damaged something with 502 glue, which caused the problem.

But this didn’t bother me too much. The valuable experience I gained will guide me in my next projects and fuel my curiosity for learning and creating.